CURRICULUM VITAE

Summary

Highly adaptable experienced mechanical engineer with a wide ranging experience across many industries. With a flare for engineering communication and is always hunting for the next problem solved with a talent for selling engineered solutions.

Profile

I started my career many years ago in the merchant navy. I was one of the shipboard engineering officers, their role is to operate and maintain the ship's plant. I started as a cadet and eventually worked up to the rank of Gas engineer on LNG carriers. As Gas Engineer I was incharge of the entire cargo system for loading and offloading the worlds largest LNG carriers

As an engineering officer I learnt to maintain and operate a great deal of plant including diesel engines, generators, Steam turbines, boilers, pumps, centrifugal separators, potable water makers, tube coolers, plate coolers, motors, hydraulics, compressed air systems etc.

This gave me a wide ranging technical base which lets me see things and solutions that others can't.

A long exposure over the stern of an LNG carrier

SKILLS

Wide ranging knowledge of choke and control valves including trim, actuation, instrumentation and controls

Excellent understanding of ball valves both supply of complete packages and repair of valves.

Experienced plant/process operator experienced in running of large propulsion diesels, marine high pressure boilers, steam turbines, turbo feeders, HV 3phase generators, HV electrical distribution systems, Diesel electric propulsion, large steam plant, centralised cooling systems, HVAC systems, refrigeration systems, cargo plant, heat recovery and fire fighting systems etc

Highly skilled in working as mechanical fitter. Fully experienced in fault finding, overhaul and maintenance of diesels from 7.5bhp to 75,000bhp, steam turbines, turbo feeders, boilers from 8 bar to 65 bar, centrifugal pumps, positive displacement pumps, air compressors, fans, centrifugal separators, gate valves, globe valves, fresh water generators, plate coolers, heat exchangers and steam traps etc.

MIG, TIG, MAG welding, flame cutting Plasma cutting, milling and turning

Undertake fault finding in both heavy electrics and electronic control systems.

Good basic skills in fault finding and repair in large hydraulic systems especially valve control

Good knowledge of CBM including vibration monitoring and oil analysis

Undertake risk assessments and work within a permit to work system

Incident investigation and root cause analysis

Manage budgetary requirements and work within budget restrictions

Ability to train people and pass on my skills easily

Work confidently under my own initiative with minimal supervision but know when to seek advice

Proficient and confident in using microsoft office suite, e-mail, SAP, SAGE 500, Fusion 360, Microsoft projects, using squarespace

Life then took my career ashore into the north sea sector

My first job ashore was as a yard mechanic for BJ Services where I learnt about nitrogen pumping and how it was used offshore for nitrogen purging and for leak testing.

From there I moved to Camerons controls where I learnt about subsea controls on trees.

I then moved across to Masterflo Chokes where I spent almost 5 years learning about choke valves both surface and subsea. I gained a large amount of knowledge about erosion control as well as API and ASME standards. As well as the day to day requirements and standards of different operators.

I was then tempted over to Control Valve Solutions as their Aftermarket Sales engineer. Here I expanded my knowledge on the world of valves. I learnt about isolation valves and how they fit into the ESD system when they are actuated. I also learnt more about control valves and the instrumentation they need when they are used in an Anti-surge application on the gas compressor train.

Redundancy took me into IKM valves where I was helping to build a valve department from nothing where I was part of a team of 3 which saw me doing anything needed. One day in a business suit the next day in a boiler suit.

I was then tempted across into business development for a small pump based engineering company out of glasgow. A role which saw me touring the highlands dealing with many customers including many distilleries. I became the inhouse valve expert as well using my experience with valves to work with pumps.

Then covid happened

In a dead job market I took a sideline and hobby of sharpening into a full business as well as another sideline in 3D printing

Work history

Damper Technology Ltd

Application engineer

May 2023 to present day

DTL are a company producing exhaust gas flue dampers ranging from small 30cm ones up to large multi-louvres up to 12m for waste heat units. With temperature ranges from ambients to 1000C.

A remote working position where I am doing the sales side engineering of the company dampers. Taking customer specifications and building up an engineered solution to meet the specification. Producing costings while working with engineering to cover any non-standard problems. Getting quotes for materials, actuators, positions and other ancillaries. Updating company Salesforce and Sharepoint portals with quote status.

Dealing with customers when the Business development team are busy.

Handing over orders to the operations team when an order has been won

Barras 3D

Sole trader/part time position

December 2021 to present day

An offshoot from barras blades. Using my skills with 3D printing and CAD I had created tools for myself. When other sharpeners saw these they wanted them. These ranged from simple belt hangers and on to the more complex McRideline. This created a demand for my products which gave me an excuse to create a small 3D printing operation with the motto of “tools not toys”

Achievements

Delivering a quick and cheap solution to local farm for replacement parts for his grain sorter

Developing the blade push used through out the world

Developing the McRideline which has been sold to the UK, mainland europe, america and Australia

Developing the slitting knife jig that lets me sharpen slitting knives for a mattress factory

Barras blades

Sole trader/part time position

June 2020 to present day

Taking a hobby of sharpening knives into a full time business. Expanding to provide sharpening services to commercial kitchens, hairdressers, groomers, tree surgeons, vets, stables, joiners as well as domestic customers.

Learning skills in sharpening almost anything that has an edge

Day to day running of a small business selling my services to customers and keeping customers happy while constantly exploring new avenues for the business and investing in new machinery without breaking the company budget.

Running company accounts and building systems to track work and diary.

Company has been scaled back since I took on the full time position at DTL

Achievements

Building the mobile workshop

Building a social media account with over a thousand followers

Growing company and maintaining relationships with customers and suppliers

Building a small CRM system to suit my needs

Creating and maintaining the company website (https://www.barras-blades.com/)

Lockdown project and home office

While not planned as the lockdown project it sort of became one as the materials and steel etc had been started while I was at Ritmac.

It is a two story steel framed office with everything apart from the concrete base being done by myself. Downstairs there is a double height section that will allow a 2 post lift to be installed at some point. Above this is a storage area which has been taken over by the dogs as they can use the large window at the end for watching the world go past.

Upstairs there is a large dedicated office (9m by 2.8m) space upstairs where I can work from home, at the end there is a large double door opening out onto a covered balcony looking over the local fields. It has fibre internet with a constant 100Mb/s up and down speed as well as a dedicated UPS. Two very large desks built by myself, with each desk being 1.7m by 2.4m. This creates a nice quiet office environment a short walk from our house as I find this suits me very well as a working environment.

Some pictures below, and the downstairs is never tidy as I always have at least one project on the go

Ritmac engineering

Business development manager

December 2018 to March 2020

Ritmac is a engineering company based in Glasgow whose core business is pumps and related equipment.

My job description was

Taking over sales in the north of Scotland which had been neglected for many years and working to build up a new customer base from historical customers and new customers.

Researching the local market and finding new customers and booking appointments as well as cold calling when opportunity allows.

Planning my own diary and working out visit routes to ensure each day on the road was as full as possible. As well as entering everything into the companies in-house CRM system.

Carrying out site surveys to allow correct pump selection as well as fault finding within customers systems. Carrying out deliveries and collections when needed as well as providing mechanical support for breakdowns and installations.

Building on previous experience from the marine world and oil and gas to build up my pump knowledge

Also acting as the company inhouse valve expert

Achievements

Increased sales figures for Northern Scotland

Reintroduced some dead accounts back to the company

Solved a issue for a seafood factory relating to supply of an unusual pattern motor on a long lead

Project managing pump installation in a local factory

Sometimes the Daphne wanted to go along to visit a client

IKM testing

Valve operations engineer

April 2018 to November 2018

IKM testing had just started up a valve department and I was a third of it

A wide ranging role which was one day carrying out business development and the next driving the company van to deliver a customers order.

Amending and writing procedures relating the valve department operations while integrating the valve department into the larger IKM group to provide a one stop solution for all pipeline, process and valve problems

Carrying out strip and inspects of customer valves and then writing reports and repair quotes. Then carrying out the repairs after the order had been won

Operating IKM mobile PSV test container both in company yard and onsite for customer PSV campaigns

Achievements

Winning work for a new company in the market

Building up the workshop procedures and equipment

Getting the company test bay adapted for use with valves

Carrying out a successful PSV campaign at a local tank farm

Repairing the companies PSV container and correcting operating procedures for it

No pictures from this job so have a picture of me with the dog

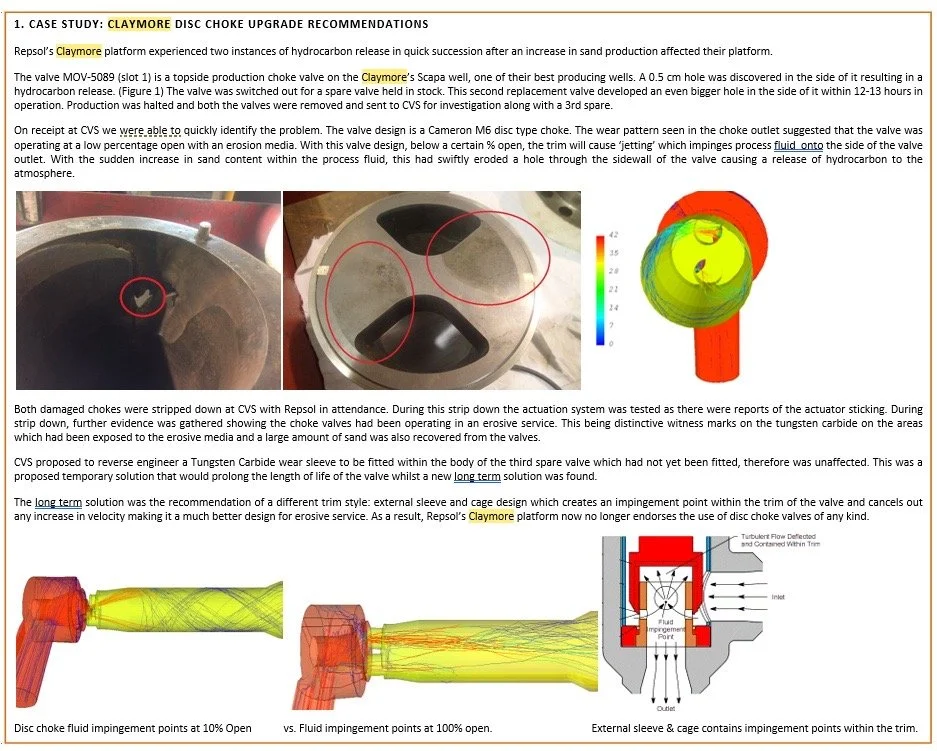

Control valve solutions ltd

Aftermarket sales engineer

January 2016 to November 2017

Control valves solutions (CVS) is a leading valve overhaul and supply company in Aberdeen supplying the oil and gas sector

This was a split role between dealing with aftermarket repairs and upgrades on customer valves and also producing quotes as part of the inside sales team.

I was brought into the team due to my experience with choke valves which I quickly applied to control valves so I became now the lead in inside sales and aftermarket for choke and control valves.

For Aftermarket repairs I would take the valve condition report from the workshop and then build up a quote to repair the valve using OEM parts, reverse engineered parts, external vendors and the inhouse workshop. This would be taken and built into a package in the inhouse software that would build up a cost as well as building a BOM for purchasing and the workshop. This would then be presented to the customer in the form of a quote. If this quote was accepted the purchasing and workshop departments would take over the running of it but I would always be available to step in if errors occurred. Each quote would be delivered with a valve condition report for the client. Should it be required I would also produce a more detailed failure report

For new supply I would work from the customers requirements and build a quote to meet it. For isolation valves I would procure the valve separately and then build an actuation package inhouse sizing and quoting the actuator taking into account torque and MAST figures. Items such as solenoids, valve indication, positioners etc would be taken from CVS stock.

For control valves they would normally be purchased with a matched linear actuator and then a controls package of postioner, boosters, surge tanks etc would be made up.

While this was an internal role I would be frequently meeting with customers in their offices either on my own or in support of the external sales team. I would also host customers if they wished to witness a valve stripdown

As part of inside sales I would be working towards company KPIs.

CVS also run an inhouse valve management database which i contributed towards its development with ideas and concepts on how it culd be improved to make my life easier.

Achievements

Identified a customer had soft seated ball valve in a line outside of acceptable temperature range which caused multiple failures, replaced with metal seated valve

Sold and delivered an actuated high performance butterfly valve package from stock items to replace failed IG vent valve in 6 weeks when OEM wanted 16 weeks and a higher cost while delivering a higher margin for CVS

Project managed and engineered with various sub vendors choke replacement and refurbishment for Repsol Claymore platform after they suffered two production choke failures in rapid succession. Bringing in over £300K to CVS over numerous orders

Project managed water injection chokes refurbishment and re trimming for AMEC/Nexen Scott platform

Wayne the valve tech with a large gate valve in CVS workshops

The souvenir produced for a client after a rather spectacular choke failure

Masterflo valves

Aftermarket sales engineer

May 2011 to December 2015

Masterflo is a producer of market leading choke valves.

I was running the repairs department with a £1.5million annual turnover managing the repair and overhaul of customers chokes both subsea and surface.

Most of my time was spent quoting and project managing repairs through the workshop. A typical valve repair would start with me booking the valve into the workorder system and issuing the workpack to the workshop. Then after the stripdown and inspection I would build up a repair plan using in-house parts and labour as well as external machine shops. For more involved repairs such as inays etc i would call on the assistance of the engineering department. Once this quote was accepted i would issue the BOM to the workshop and then project manage the repair with the workshop and external vendors.

Assisting purchasing with local procurement of parts from machine shops in the UK as well as project managing the build of test and transport skids.

I would support the external sales team by providing technical support during meetings with existing and potential customers. As well as hosting the afternoon session of lunch and learns which where carried out in the workshop. As well as hosting witnessed strip and inspect of failed valves should the customer want to witness them

In the absence of workshop manager running the daily running of the workshop. Also working closely with HSE department providing assistance in writing risk assessments as well as reviewing and auditing procedures.

Achievements

Project managed major overhaul program for CNR baobab subsea insert chokes including retrimming one to deal with erosion issues

Created and sold to GE a spares package which took the turnaround time for a specialised subsea choke from almost a year to 12 weeks. This involved selling them a spares part kit which retailed at about £80,000 and the client bought 5 of them and then another 2 once the system proved itself.

Worked with Total to identify a lack of greasing causing repeated choke failures

Project managed a major upgrade of Magnus P6 chokes with inlays and revised sealing

Taking a pivotal role in introducing sage500 software for the workorders side of the system.

Cameron controls

Customer service specialist

July2010 to May 2011

An office based position working as a customer representative for cameron controls, project managing subsea controls equipment repair and rework through the Cameron controls workshops. Acting as a focal point for external clients in the UK and overseas, providing them with a central figure for contact and liaison of all issues relating to their Subsea Controls systems. Communicating to our clients electronically, via telephone and face to face meetings.

Over all, my duties are planning and implementing the maintenance schedule for client’s control equipment which includes controls hydraulic power units, control panels, umbilical reelers and subsea jumpers

Providing technical support to ongoing offshore operations.

Achievements

Project managed bringing an abandoned HPU and controls package out of neglect in the corner of the yard into a full functioning package for use by BP

Brought in the use of Rivnuts and tooling to ease the refitting of access panels

BJ services

Mechanical service technician

July 2008 to July 2010

A workshop based position as a yard mechanic Dealing with high pressure liquid nitrogen pumping units and carrying out routine maintenance as well as breakdowns. During the off season we would also carry out complete refurbishments of any pumping units that needed it.

As well as maintaining the pumping units we would carry out all yard based tests would involve setting up the Nitrogen pumping units, cooling them down and running on test and then breaking them down for shipment back offshore.

We would also look after the Nitrogen tanks which we would fill from the yard tank as well as maintaining them when needed

Dealing with mostly Detroit and caterpillar diesels, hydraulic power transmission systems and pneumatic safety/control systems. Fault finding in hydraulic and pneumatic systems. Taking part in third party inspections of machinery. Full safety checks before dispatching units offshore. Working with permit to work system. Driving forklifts up to 16ton within the yard

Achievements

Identified and implemented a method of finding faulty cold ends on nitrogen pumps using a water hose that replaced basically guessing

Complete stripdown of 2 nitrogen pumping units to individual parts, refurbishment of the Detroit engine, replacement of all hydraulic hoses, repiping of shutdown system & control panel, fitting of refurbished coolers & radiator, repainting of stripped assembly, rebuild and test run for delivery back into the hire fleet.

MolTank

Gas engineer

August 2003 to March 2008

Gas Engineer on modern LNG vessels with ten years experience in marine engineering. Solely responsibly for all cargo related equipment on deck. Duties include management of cryogenic valves and piping, cargo containment systems, cryogenic cargo pumps, LNG vaporisers and heaters, centrifugal gas compressors, return gas blowers, inert gas generators as well as non cargo related equipment such as winches and cranes.

Jointly responsible with Chief Officer for all loading and unloading operations of bulk LNG cargo. Taking command of entire cargo operations while chief officer is on rest periods Liaising with shoreside personnel in many different countries to enable connection operations to take place. Working closely with Chief Officer in preparing cargo operation plans, also planning unusual operations such as gas freeing and inerting operations. Progression of cargo operation plans through to completion.

Achievements

Identified a secondary barrier failure in a Technigaz Mk3 cargo tank leading to a substantial warranty claim against the builders

Inerted and gas freed vessel for tank entry and subsequent shipyard time

Inerted, gassed up and cooled down vessel to allow her to return to service

Stood by building and commissioning of LNG vessel Murwab of Q-flex class

Dragging an DSLR camera around the world and taking alot of pictures see below