Sharpening a clipper blade

A story in pictures of the basic process for sharpening an A5 clipper blade.

Gather all the tools needed

We have a tray of clipper blades

A blade scale, flat bladed screwdriver, a Philips screwdriver, a socket tool, a tool brush, a pair of water pump pliers

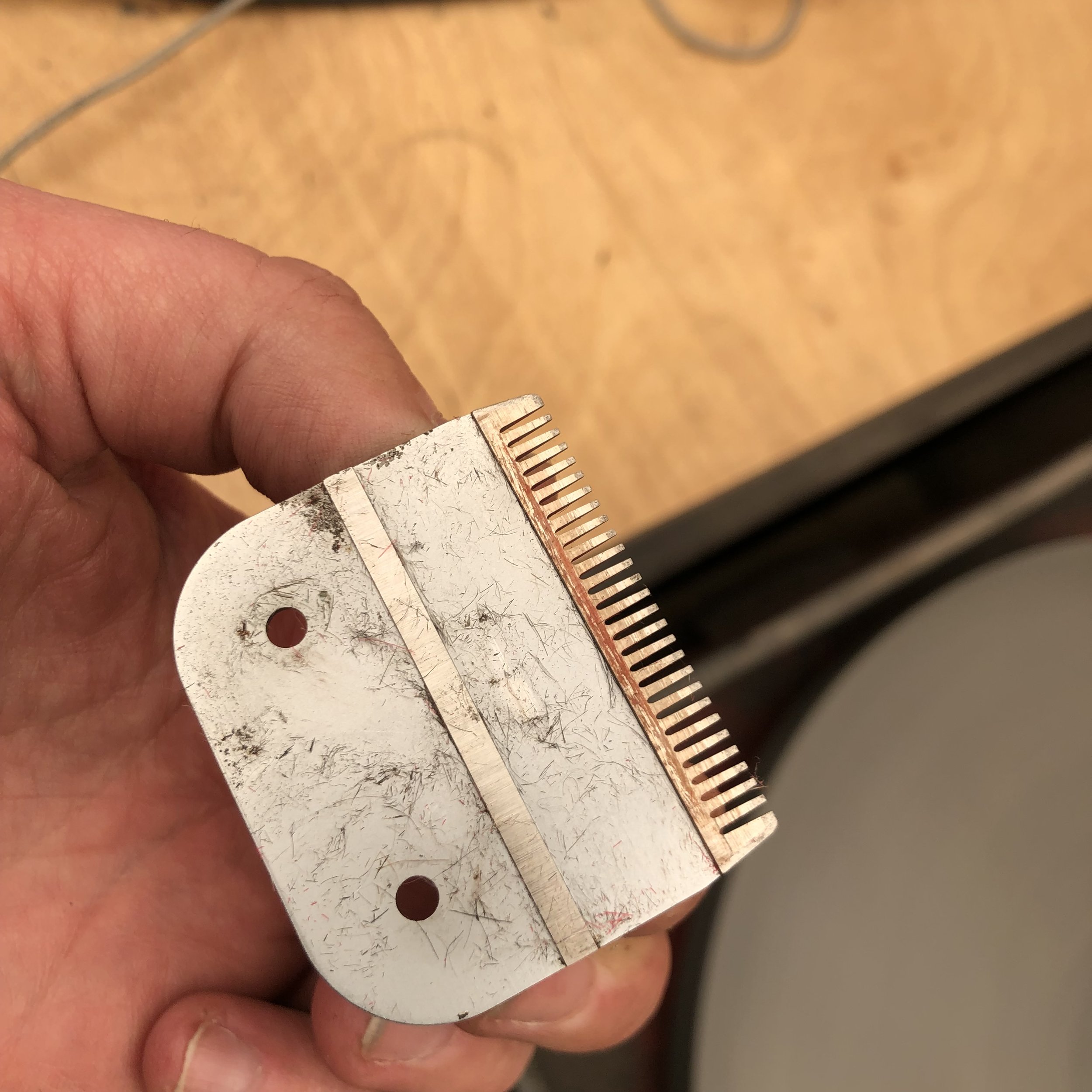

Inspect the blade

Quick look to see if anything is obvious

Strip the blades

Give them another quick inspection

Mmmm someone hasn’t been cleaning their blades

Socket and spring

Pull the spring and the blade socket out of the pile and give them a quick clean

Set the socket

Using the socket setting tool place the blade socket over it and squeeze the ears so they are back to the width they should be.

The ears tend to widen with use which makes the blades loose and rattling on the clipper

Side note!

Not part of the repair sharpening process but this is how the socket sit on your clippers

back to the process

Increase the tension

Put the socket back in the tension spring

Then squeeze the base down so you will have too much tension when assembling the blade

Stick to the magnet

A small horseshoe magnet is attached to the back of the comb so it can be used as a handle

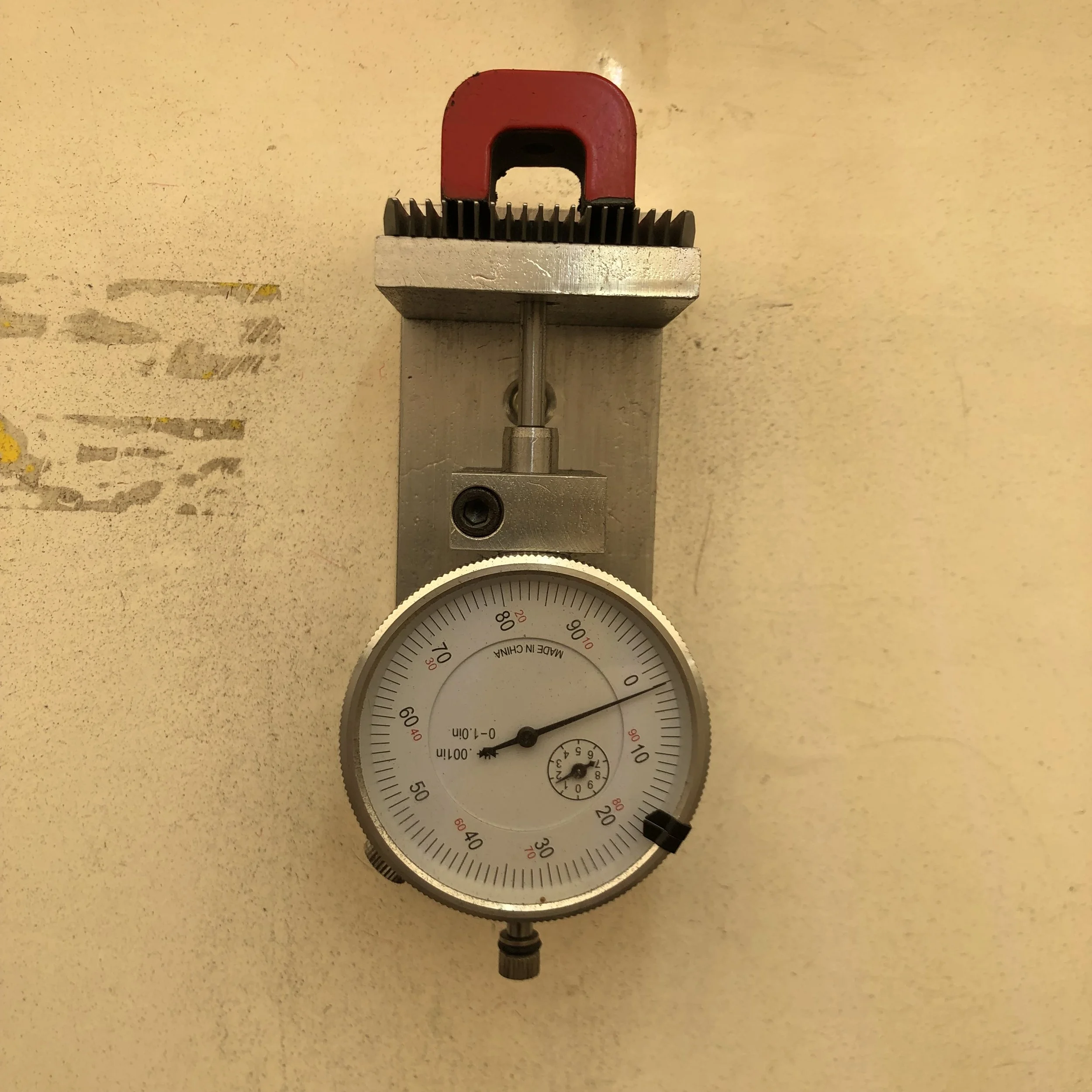

Zero the gauge

The blade is put on a DTI stand which will measure material removed.

Another inspection

With the comb on it’s own this is an ideal time to check for damaged teeth

Actually I do this inspection afterwards as well but I forgot to take a picture

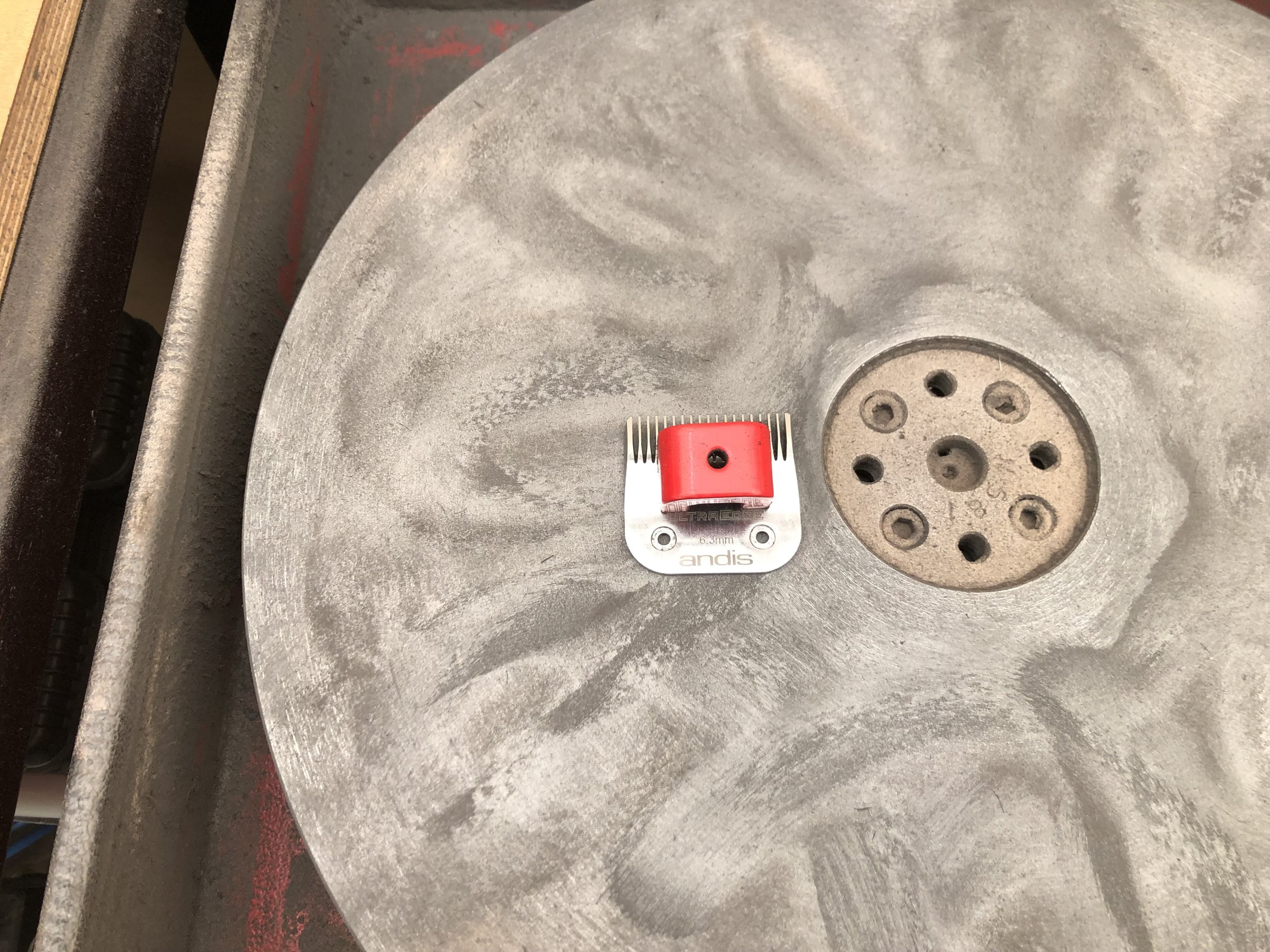

Grind the comb

Using the big red a hollow grind is put into the blade.

See the BIG RED page for more details on this step

Measure the material removed

Back on the DTI and you are aiming for 2 thou to be removed

This isn’t done on every blade as I have a good feel for it so about half are measured to give a good sample

Grind the cutter

The cutter isn’t measured but it is sharpened the same way on the same machine

That brown stuff is a lack of oil and/or cleaning

Do the lot

Repeat the grinding for each blade pair.

Made a magnet

See how I attached a magnet to the comb and then warmed it up using the grinder.

It is a great way to make a magnet which can pick up screws and all sorts of bits of metal.

Demagnetiser

A tool which does what it says on the tin.

By stroking the cutter and comb across this it is demagnetised.

Some people do this at the end for the completed blade but I think now is a better time as it stops the blade parts from picking up metal dust

Deburr

A quick clean between the teeth with the brass toothbrush and a good blow with the airline removes the burr from the grinding as well as gets rid of cack between the teeth

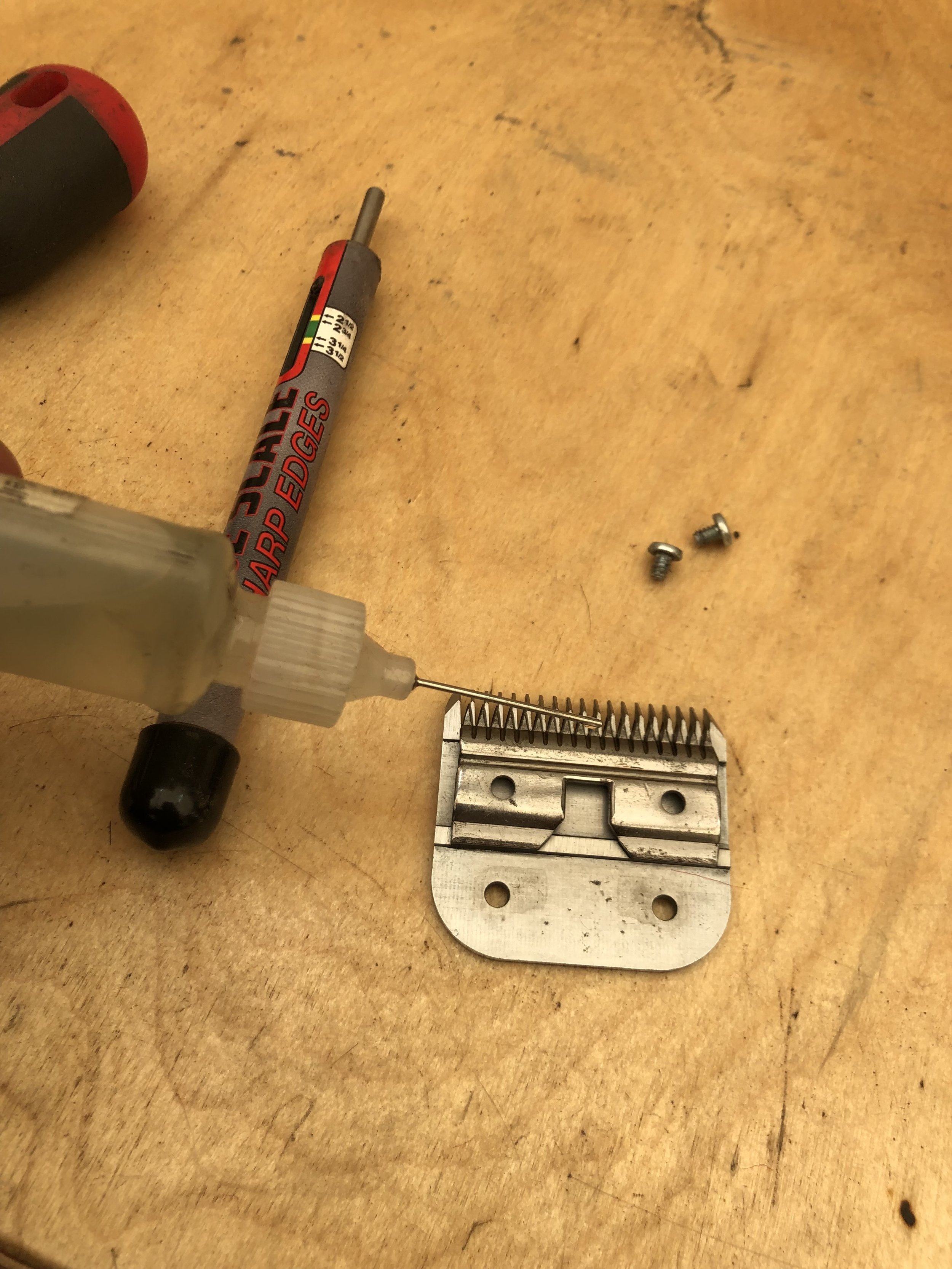

Reassembly tools

Gather all the parts together to reassemble the blade.

Including the blade scale which is vital when rebuilding blades

More info HERE

Oil the blades

A good dose of oil in the correct places and then sit the cutter on the comb and a wee shot of oil onto where the glide strip sits

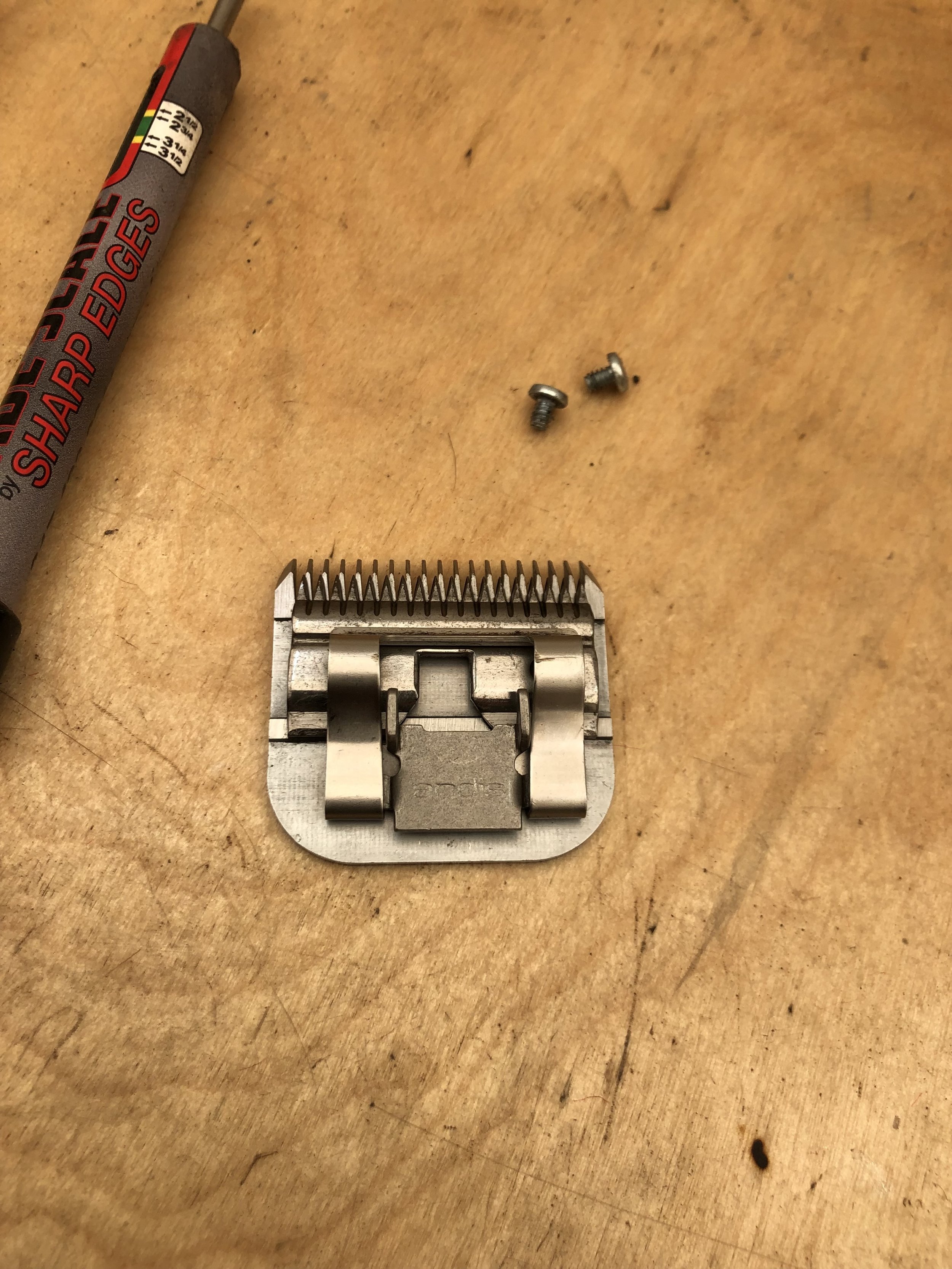

Tensioner and socket

Place the tensioner and socket onto the blade assembly

Pick it up

Now carefully pick up the entire stack gripping it in the way shown.

You can also see how the tension spring is sitting up as there is no tension on it.

Line it all up

With much fiddling and practise along all the parts so the holes line up and you can put the screws in.

Cutter set back

The cutter needs to be set up with the correct set back from the teeth on the comb

This is way too far back

Cutter setback

This is far too far forward. If it was a short cut blade then this would be really bad as the moving teeth could contact the dog’s skin.

Correct set back

This is about how much set back you want

Do remember the cutter moves forward when you tighten down the tension spring.

Measure the blade tension

Oh look this blade has too much tension as it should be near the top of the green.

Which is exactly as planned as I increased the tension right at the beginning.

Remove the tension

Using a flat blade screwdriver you can remove some tension.

This is massively easier than trying to add tension to a fully built blade

Perfect tension

This is where you want the tension to be

I cheated for this picture as it’s a moving tension which is a bit too difficult to picture.

Final test

The blade is fitted to a clipper and is tested with some fake fur.

if it passes then it is packaged up ready for the customer