A key development

One of the first companies to help us out with a dropbox was Mearns hardware in Laurencekirk. Sadly due to increasing costs and falling business they had to close their doors. One of the services they offered was key cutting which i have taken over.

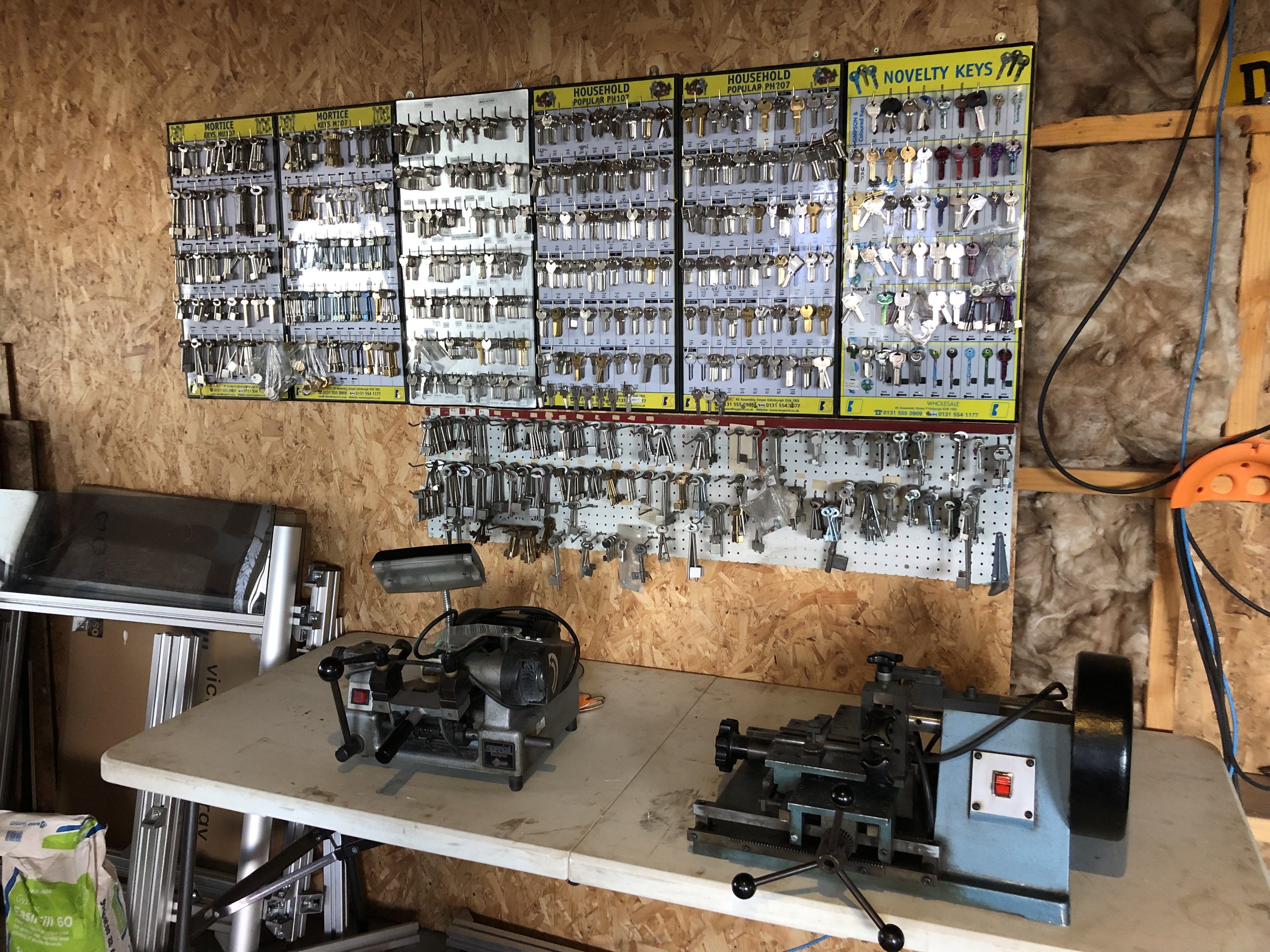

I purchased the two machines for doing mortice style keys and cylinder style keys as well as a huge amount of blanks of varying usefulness. Want a key cut for a 1980’s volvo then i’ve got one in stock.

So how does key cutting work?

There is two parts of the operation

Firstly you have identify the key blank which is harder than it looks as their is hundreds of different lengths and profiles of keys. Todo this there is

First clue

The key has a nice little number on it which indicates the key blank type.

In this case ER2D

Next clue

If there is no number on the key then there is a profile plate where you can try to workout the profile

Actually there is more then one profile plate

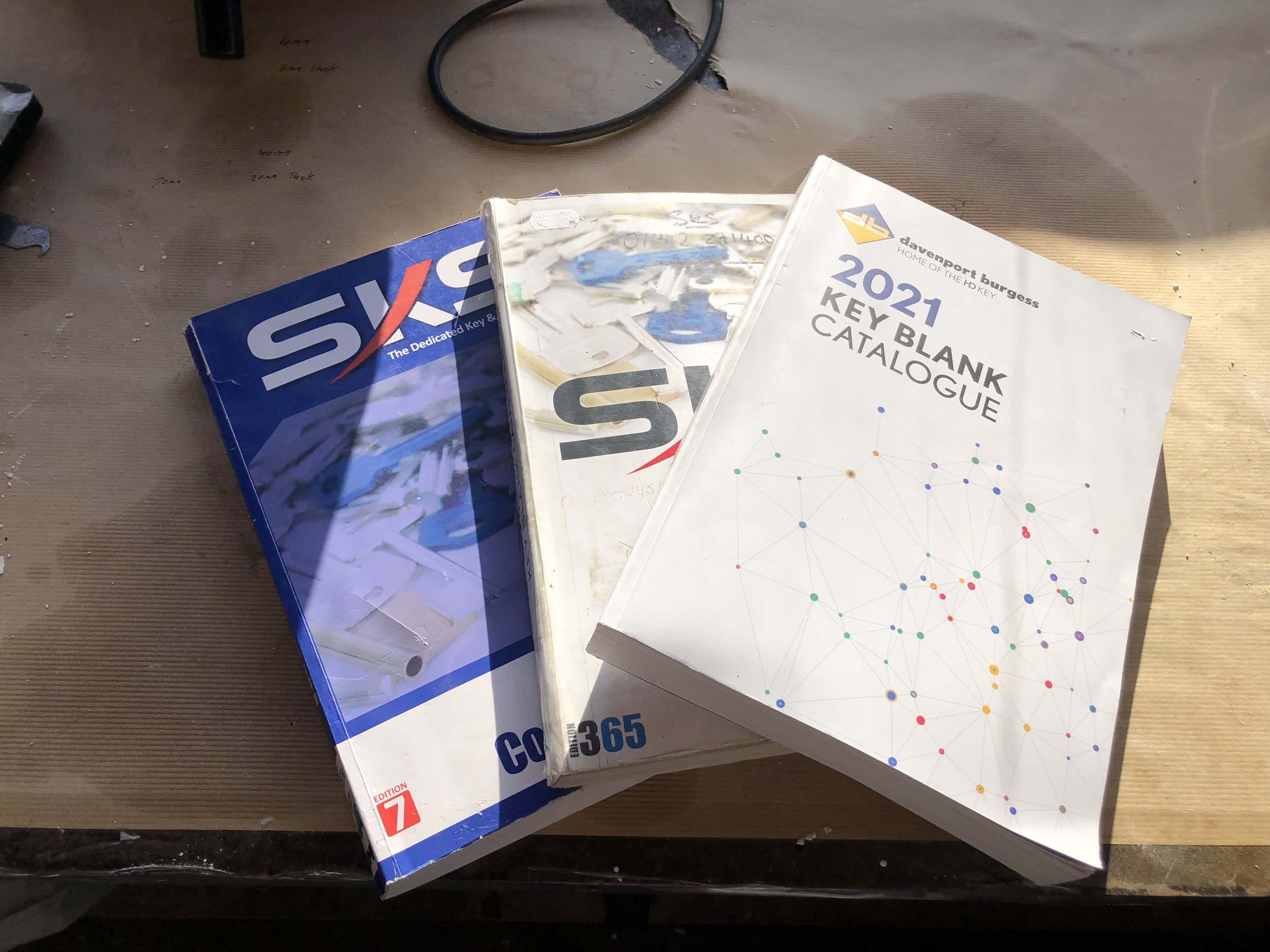

Then there is the fun of pouring through this little lot to find out the correct blank

Then finally

You can find the blank hanging on the rack (hopefully)

Then once you have selected you blank it is onto copying the key using the machine which takes the profile of the old key and cuts it into the key blank.

The cost to myself as a business comes from two sides. There is the cost of the blanks which can vary from not very much for a common blank to alot for the rarer blanks. The other cost is my time in copying the key as well as energy costs etc.

So to this end i think i’ll be undercutting the high street chains as i don’t have any costs from running a shop as well as it being a sideline so a typical cost will be about £5 per key with reductions if there is multiples.

How will it with barras blades?

At the intial moment I won’t be offering key cutting at the pop-ups as i’d need another trailer just for the machines and the blanks. This may change as I sort the blanks into popular ones and rare ones. Then i will be able to take the popular ones along to pop-ups.

For the mobile workshop I might b able to oocasionally offer this if you have alot of keys to be cut of only a few types.

The main way it will be operating just now is in 3 basic ways which needs the keys brough back to base for identification and then copying.

There will be drop off at base where if we can we will do while you wait.

There is collect and return as well as the dropboxes

For the drop boxes it is probably best to put the keys you want cut in an envelope along with a note on how many. I will probably create a form for it (I like forms)

What next for key cutting?

The first job will be to properly catalogue all the key blanks as in addition to the 6 racks pictured there is also two sets of drawers and a couple of baskets of blanks. This will let me both make it uicker to find oddball keys but it will also put into my mind what there is.

As a further progression I might do some training as a locksmith as I’m already working out of a mobile workshop, i’m very mechanically minded and i already have an quite good knowledge of locks and doors. I could also move into cutting keys for modern cars but i do considered most modern electronics etc to be witchcraft